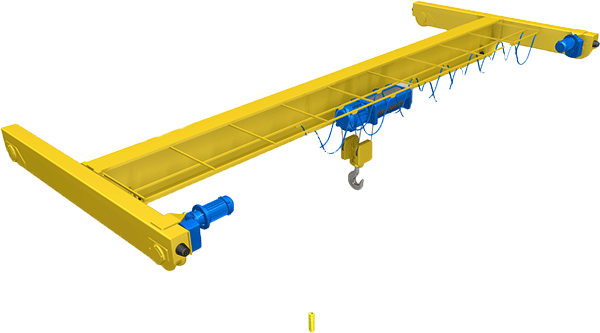

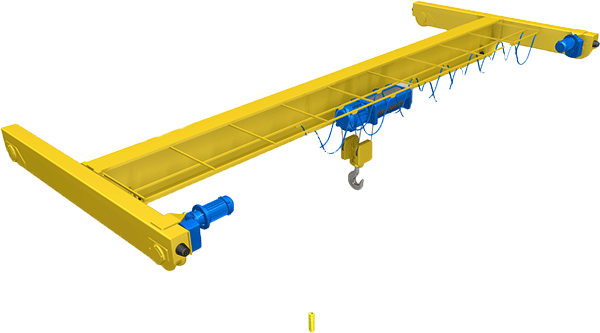

Single Girder EOT Crane

Single girder overhead crane is a kind of crane travelling along two parallel rails and lifting mechanisms travel along horizontal main girder. Single girder overhead crane is composed of main girder, end girders, traveling mechanisms, lifting mechanism (hoist) and electrical components. This crane is usually used in long distance workshops and runs along the rails on both sidewalls.

Specifications

- Capacity: up to 16 T

- Span: up to 35m

- Lift Height: As per requirement

We offer Single Girder EOT cranes with welded box construction and rolled steel sections which could be accommodated based on the available space over the Gantry Girders.

In a Single Girder EOT Crane the hoist travels with a monorail electric trolly on the bottom of the Crane Girder which is a cost effective solution to the customer.

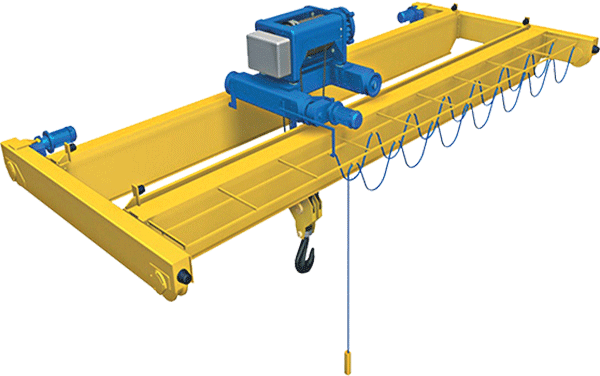

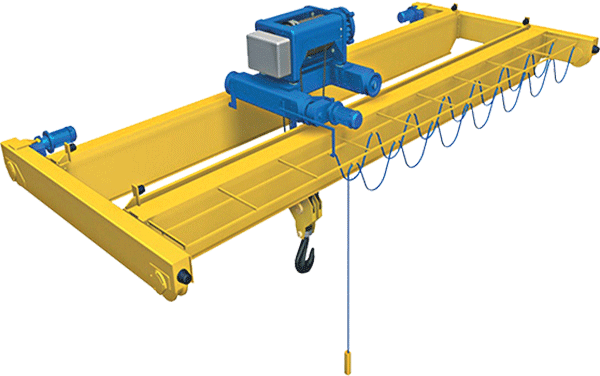

Double Girder EOT Crane

Double Girder EOT Crane is rigidly constructed with welded Box girders to achieve greater stability through even load sharing. It is recommended for higher capacities and larger span with heavy service duty cycle and Critical Applications.

Specifications

- Capacity: up to 160 T

- Span: up to 34m

- Lift Height: As per requirement

In a Double Girder EOT Crane the hoist travels with a crab trolley on the top of the crane girders which offers maximum vertical hook access.

Cranes shall be configured with multiple hoists which enable tandem operation for handling larger components.

Gantry / Portal Crane

Gantry Cranes / Portal Cranes travels on either sides of Long travel rails fixed on the floor and rest of the operations are same as EOT Cranes.

Specifications

- Capacity: up to 50 T

- Span: up to 30m

- Lift Height: As per requirement

This type of cranes is used in the area where the building was not designed to bear the crane load and the outdoor applications where there is no building coverage.

Viability: Capacity of up to 100t with the span of 30 meters. Both Single Girder and Double Girder options are available in this model.

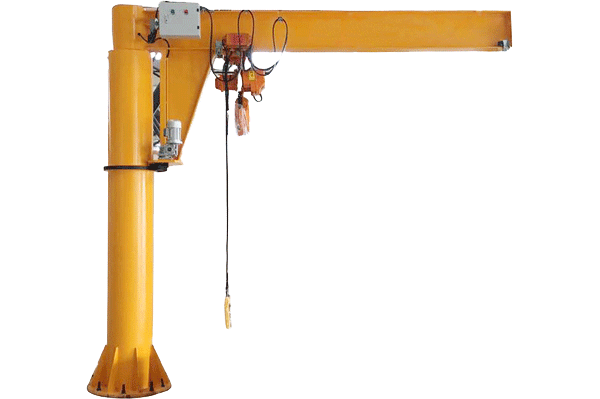

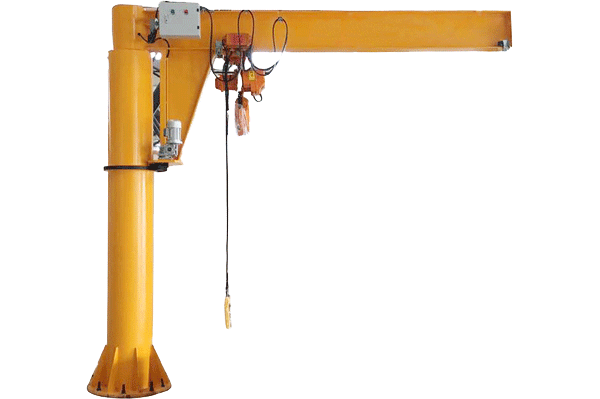

Pillar Mounted / Self Supported Jib Crane

Pillar Mounted Jib Cranes are perfect solution for individual workstation where the crane is deployed for specific task to reduce the lead time. They are used for Loading & Unloading of materials from vehicles and also to load & unload the materials to the machine in a machine shop.

Specifications

- Capacity: up to 10 T

- Span: up to 10m

- Lift Height: As per requirement

The slewing arm rotates 90° / 180° / 270° / 360° with manual /electric operation.

Slew Electric drive comes with variable frequency drive which helps in smooth and precise operation in material handling.

Work station Cranes / Light Crane Systems

Light crane system is another variety of overhead travelling crane with a light weight supporting profile. In this system the long travel profile is suspended on the on the bottom of the runway Girder, where the cross travel profile is suspended on the bottom of the long travel profile and the hoist on the cross travel profile with Push pull trolleys.

This system enables the operator to easily position the Job/Material on the exact required location through manual movement. Mostly Hoisting application alone will be electric / motorized in this system.

This system can be directly supported from the building truss/beams and also the support can be taken from free standing columns. This Kind of system is mostly used in assembly lines of Automobile industry and in industries involves in cyclic processes with light weight components

Viability: Safe working load range starts from 100kg to 2t with a span of 6 meters.